Installation is a straightforward process requiring only standard tools. You don’t need to haul it out if it’s in the water, which can save you considerable expense. The messiest part is getting rid of all the old fossil fuel-related equipment: engine, fuel tank, venting and filler, water cooling system, muffler, and exhaust system.

Once the old engine is removed, clean the engine compartment and bilge. This is a good time to give the old engine compartment a coat of bilge paint. You can expect it to stay clean and odor-free. As one of our customers advised us: ” it may need an occasional dusting!”

Install and secure the batteries. This is the most time-consuming step. The most common location is under quarter berths adjacent to the engine compartment and the engine compartment itself.

Install battery chargers, battery fuse, relay (solenoid), and master power switch.

Mount the throttle quadrant and battery monitor in the cockpit or on the steering pedestal. Run their cables into the engine compartment and plug them into the respective sockets, twisting the lock-ring.

Lift the new motor assembly into the engine compartment.

Adjust the mounting feet to line up the output shaft with the prop shaft.

Slide the coupling on the prop shaft, tighten the clamp.

Secure the mounting feet to the engine rails with the furnished stainless steel lag bolts.

Measure the battery cables for a nice tidy installation, secure them, and you’re done!

You don’t have to be in the water to test your system, and if your boat is on the hard, it allows you to remove the underwater completely

OR

Reach out to one of our local installers:

California Installers

Sean Shigley- [email protected] - San Francisco / SLO/LA/SD - 805) 704-2782

James Hildebrand - [email protected] - San Francisco, CA - 707 656 9698

Cree Partridge - Berkeley Marine Center - [email protected] - berkeley - 510-843-8195

Luis or Alison - [email protected] - Bay Area Marine Services -

Richmond - (415) 203-6305

Ian Ferguson - [email protected] - Berkeley, CA - (530) 721-3024

Chris Forrest - Santa Cruz Marine Services - c[email protected] - 831-515-9991

David Doyle - Refit Marine - [email protected] - 510-253-5883

Brian Perrin - [email protected] - San Diego, CA 92101 - (619) 518-5685

Tom Wilder - Land or Sea Electric - [email protected] - Half Moon Bay, CA - 650 479 6232

Chris Hugh - [email protected] - Los Angeles, CA - (310) 809-6627

Rob - Min Mar Marine - [email protected] - Long Beach - 562 590-5055

Dave New - Basin Marine - [email protected] - Newport Beach, CA 92660 - (949) 673-0360

Richard Stizzi - Vessel Care - [email protected] - Newport Beach - (714) 747-4036

Gary and PK - First Watch Marine - [email protected] - San Diego - (619) 916-1730

Motor Sizing and Diesel/Gasoline Engine Equivalency

The first step in designing an electric propulsion system is choosing the right motor size. Below is a chart that will provide general guidelines. Contact Electric Yacht, or one of our dealers, for more specific information and assistance in making a selection.

Diesel “Equivalency”

Some suppliers of electric propulsion have claimed an electric propulsion motor is “equivalent” to a diesel engine of 2-3 times higher horsepower rating. On the surface, these claims seem confusing and untrue. It takes a certain amount of horsepower applied to the propeller shaft to propel a boat at a given speed, regardless of the power source. However, several factors lend legitimacy to these claims

Rating Systems

First of all, diesel engines are usually rated in brake horsepower (BHP). This rating does not subtract losses in the transmission, alternator load, or water pump load. The net shaft horsepower (SHP) the same engine actually produces, can be anywhere from 10% less on a larger engine to nearly 50% less on a small one-cylinder engine.

The Propeller Curve

The power required to push a displacement hull with a 25’ – 40’ waterline length will increase 1.5- 2 times for each knot of speed. Since many diesel boats are overpowered to achieve “hull speed” (usually defined as 1.34 * sqrt(LWL)), an electric motor of lower rating will often result in little or no loss in motoring speed.

Maneuvering Thrust

Finally, an electric motor for maneuvering will provide superior performance to a diesel or gasoline engine of a higher rating. The ability to slow the electric motor well below an ICE’s idle speed, combined with full torque at any speed, makes for superior maneuvering performance. In addition, no starting, warm-up, and quiet operation of an electric motor makes for superior overall performance.

Add all these factors together, and it may be appropriate to replace an ICE of greater horsepower rating of the electric motor. Contact Electric Yacht or one of our dealers for assistance in sizing an electric motor for you.

Generally, power curves you may find online are not very helpful in defining how the motors will perform in an application. They are generated by running a motor at a constant voltage and varying the load on a dynamometer. This is useful for companies like Electric Yacht, when designing a system, but not very useful for determining how it will perform in the end application.

The Electric Yacht systems are set up with a motor controller that effectively varies the voltage applied to the motor. By varying voltage, speed and torque can be controlled. The curves in the graphs do not directly apply under these conditions.

The controllers are set up with a current limit which effectively controls the maximum torque the motor can apply. From zero speed to a maximum determined by the battery voltage, the torque “curve” is a flat line limited by the amount of current the controller will supply to the motor.

This also is not very useful, except it will determine the maximum available torque. In use, the motor is driving a propeller. Therefore, it is much more useful to plot current or power against shaft speed or boat speed using a propeller’s torque absorption curve. We can provide these plots. We use data from your vessel to estimate performance. The most important are LWL, displacement, and general hull type.

We use several different Motenergy motors and set the torque limits as follows:

ME1118: 24 Nm Approximate maximum shaft speed is 2000 RPM

ME1114: 35 Nm Approximate maximum shaft speed is 3000 RPM

ME1115: 48 Nm Approximate maximum shaft speed is 2000 RPM

ME1616: 78 Nm Approximate maximum shaft speed is 2000 RPM

Maximum shaft speed will depend primarily on actual battery voltage and how well the propeller is matched to the motor. The propeller shaft torque is multiplied by a reduction ratio in a range from 1.42:1 to 2.22:1 for our standard frame and up to 3.33:1 for a wide frame, we use with certain 48Vdc liquid-cooled, 72Vdc, and 96Vdc systems. Also, the QT 20.0, 30.0, and 40.0 motors use two of the ME1114 or ME1115 motors, so torque is double. QT 30.0 LC, QT 45.0 LC, and QT 60.0 LC use two ME1616 motors, so torque is doubled.

Measured efficiency under high load is in the 80% to 85% range. This is total system efficiency and not just the peak motor efficiency often quoted by our competitors. They conveniently leave out motor controller losses, bearing losses, and wiring losses that occur in any real system. In practice, a well-designed system will have similar efficiency to ours. A poorly designed one, or one with older technology components, will be less.

The Electric Yacht Engineering Team

Propeller Type

The propeller is where “the rubber meets the road,” so to speak. More accurately, for marine applications, it is where the “metal meets the water.”

Many factors determine the best choice of propeller for a given application. For auxiliary sailboats, it is often a compromise between sailing drag and performance when motoring. In particular, is effectiveness when maneuvering.

In this regard, a fixed three-blade propeller will provide the best overall motoring performance. It will also provide the best regeneration under sail. On the downside, of course, is an additional sailing drag.

There are several types of propellers in common usage. Each has its advantages and disadvantages.

In general, a two-blade fixed is a good compromise concerning overall performance and reduced sailing drag. Typically, their motoring performance is good, but they suffer reduced effectiveness when maneuvering.

Of course, feathering and folding propellers provide the greatest reduction in drag. This must be weighed against their effectiveness when motoring or maneuvering. All brands are not equal.

Propeller Sizing

Anyone familiar with a diesel repower is aware of the importance of matching the propeller to the engine and transmission ratio. The most important factors are diameter and pitch. This will determine how much power a propeller will absorb at a given shaft speed.

If the propeller absorbs too much power, the engine will be overloaded. It will not get to its designed maximum speed because it will reach its maximum torque capability before reaching the designed maximum speed (RPM). This is a serious issue and will cause engine damage.

If the propeller does not absorb enough power, the engine will over the speed at full throttle. This is also a serious issue and will result in engine damage unless the operator restricts engine speed to the designed maximum.

The situation is different for an EP motor. As long as the system is properly designed, it will not be damaged by a mismatch. However, a proper match is still necessary to obtain full power from your EP motor.

Unlike other EP suppliers, Electric Yacht can supply a range of speed reduction ratios. When properly matched, the electric motor is allowed to run at its optimum torque/speed while the propeller shaft turns at the best speed for the boat/propeller combination. In most cases, we can match your existing boat and propeller combination such that you will get the most of your EP motor.

The Battery System

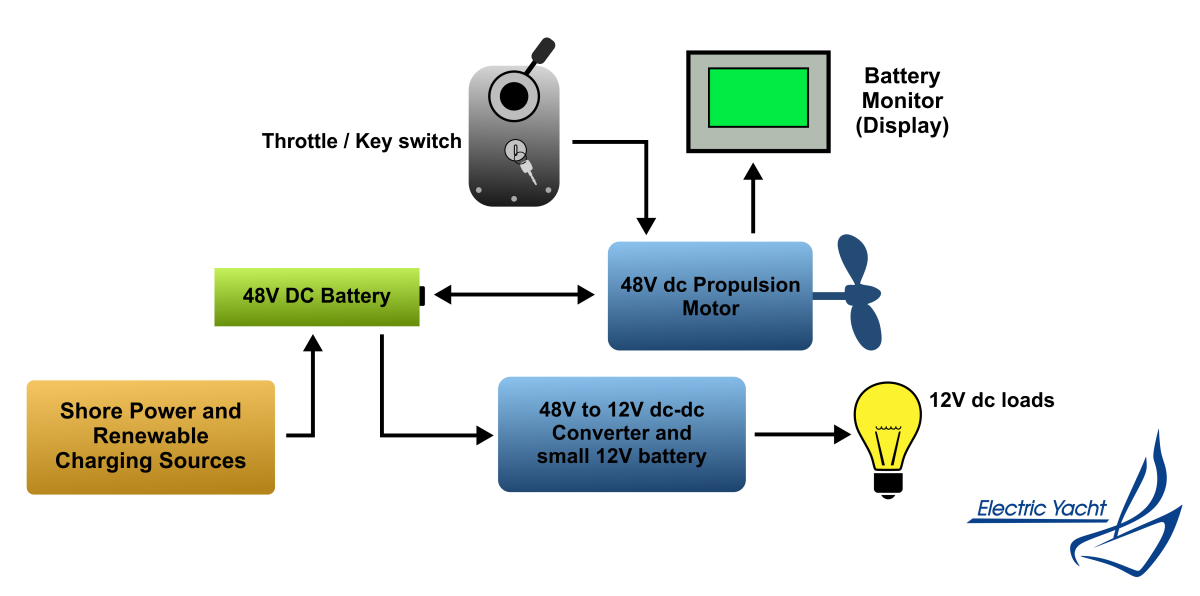

The battery system consists of a set of batteries that provide essential energy storage. Typically, this is a 6V or 12V lead-acid battery connected in series to form a 48, 72, or 96Vdc battery pack. This battery pack powers the electric propulsion (EP) motor and can also function as energy storage for other onboard (house) power needs. It can be charged by multiple sources, including shore power, regeneration under sail, solar panels, wind generators, and/or an onboard fossil fuel-powered generator.

The right solution depends on your desires and needs.

Battery Sizing

Next to selecting the right propulsion motor, battery sizing is the most important factor in designing an EP system to meet your needs. Let’s face it, the energy storage density of current battery technology is the greatest factor limiting the adoption of EP. If not for this limitation, the reduced maintenance, compact size, and quiet operation of an electric motor would render the ICE obsolete.

A compromise must be made because the storage density of batteries is substantially less than an equivalent weight/volume of fossil fuel. However, an adequately sized battery can supply the needs of most weekend sailors. Combine a small ICE-powered generator with renewable sources and the needs of many cruising sailors can be met with greatly reduced dependence on fossil fuels.

A good starting point is to choose a size that will provide an hour of runtime at hull speed. Typically, this will provide 3-4 hours of runtime at 5 knots and many hours of runtime at reduced speeds or motor sailing in light air.

This chart shows a typical example in calm seas. It is an estimated runtime for a typical 35ft 12000-pound sailboat with a 48Vdc x 300Ah AGM battery and QuieTorque™ 10.0 motor. Typically, the motor and batteries will be similar in weight and fit in the space formally occupied by the ICE, tankage, starting battery, and other removed components.

This chart provides a general guideline for choosing the best battery bank size for your boat. Racers will typically want to use minimum sizes to save weight, often reducing weight compared to replaced ICE.

Others will want as much capacity as space and budget allow. Contact Electric Yacht or one of our dealers for further assistance.

Battery Type

There are three batteries types often selected or electric propulsion. Following is a short description of these with advantages and disadvantages.

Flooded Deep Cycle Lead Acid

This type is the most cost-effective. The most common arrangement would be a set of eight 6V T-105 “golf car” batteries. Cost is the main advantage. Disadvantages include the need for periodic watering, less efficient charging and discharging, release of hydrogen gas when charging and shorter life span when deeply discharged regularly. This type is most appropriate when the budget is tight and for boats that are not heavily used. We do not recommend flooded batteries for most of our clients.

Absorbed Glass Matt (AGM)

This type is the most commonly used for EP applications. AGM batteries will last longer than flooded batteries if regularly deeply discharged. They charge and discharge more efficiently than flooded batteries, don’t outgas (unless overcharged), and don’t need watering. On the downside, quality AGM batteries cost more than quality flooded batteries.

LiFePO4

Lithium-Iron-Phosphate (LiFeP04 or “Life-Po-Four”) is the Li-ion chemistry most appropriate for marine EP usage. This type is not as energy-dense as some Li-ion chemistries, but is long-lasting and not much safer than some other chemistries. These batteries offer five times the life of AGM batteries and provide twice the energy density of lead-acid chemistries. They also charge and discharge very efficiently. The negative side is cost. Prices are coming down, but they are roughly five times the cost of quality AGM batteries. They make the most sense in situations of daily usage or where maximum capacity is key.

Depth of Discharge (DOD)

A popular misconception is that batteries should not be discharged below 50%. There is a belief among some that doing so will greatly reduce the life of your batteries. The average depth of discharge (DOD) plays a major role in battery life. It is a very common practice to size batteries such that the AVERAGE DOD does not exceed 50%. We support this practice. However, do not be concerned with discharging more deeply when necessary.

As a guideline, properly maintained deep-cycle flooded batteries will last roughly 1000 charge/discharge cycles to 50% DOD. This drops to 200-300 cycles to 80% DOD. Quality AGM batteries will also last 1000 cycles to 50% DOD but can be expected to last 400-600 cycles to 80% DOD.

The most common cause of early failure of lead-acid batteries is not deep discharge. Chronic undercharging or leaving them in a deeply discharged state is much more likely to lead to failure than discharging beyond 50% DOD. This is due to a process known as “sulfation,” which is a build-up of crystals on the lead plates that block the flow of electrons, reducing capacity. To some extent, there are ways to reverse this process. However, the best practice is always to bring the batteries to full charge as soon as possible after usage.

LiFePO4 batteries are typically rated at something like 5000 cycles to 50% DOD and 2000 cycles to 80% DOD. They do not suffer from “sulfation” and are not affected by being left in a partial state of charge.

As such, they are the best choice for high-usage applications.

Regeneration:

When under sail, place the throttle in neutral with the key switch “on” when the dragging propeller rotates, this will regenerate a power charge to the batteries. Hull Speed and Prop Shaft RPM dictate charging amperage.

We can put you in contact with an Electric Yacht “Family Member” with a similar boat to discuss real-time Regen experiences.

Solar/Wind Power:

Solar panels or a wind generator can be added to supplement regeneration and shore power charging. This is especially useful for moored boats. Solar, wind, and regenerative charging can allow the boat owner to be completely free of the power grid and fossil fuel power.

Shore Power Charging:

We highly recommend modern “smart” shore power chargers. Typically, these are microprocessor-controlled chargers that sense the charge level and step down the charging current as the full charge is approached. When the batteries are fully charged, they will turn off. This prevents overcharging. A good quality charger designed for the specific type is a must if AGM or Gel batteries are used.

1. Lightning protection.

There is some evidence that having your rigging and everything metal connected to a common grounding point will provide some level of lightning protection. However, there is no conclusive evidence. This is the case where you would ground to a keel bolt. Better is an exposed bronze “shoe” on the outside of the hull.

2. Electric shock.

All of the low voltage dc negative connections (the 12Vdc system and the 48Vdc system in our case) are connected. Also, the ac ground is connected to this ground, as well. The theory is that with one side connected everything will have a common reference and the chance of touching two pieces of equipment or wiring causing a shock is minimized. This is in the ABYC standard E-11.

3. Galvanic corrosion.

This gets somewhat complicated. Traditionally, it was recommended to connect all metal through hulls, rudder posts, and the engine. This makes them all at the same potential. It allows sacrificial zinc connected to any one of these to protect them all. It makes perfect sense when the boat is free of shore power. However, it increases the chance of damage to everything that can be caused by improper shore power grounding in your boat, or your neighbor’s, or the marina wiring itself. In recent years there is a trend of getting away from bonding everything metal that touches seawater together. It is to lessen the risk of problems when connected to shore power.

Actually, a floating system has a great deal of merit in preventing the kind of issues that can happen when connected to shore power. Volvo made this possible years ago with their sail drives by electrically isolating the drive from the engine. The engine is still connected to the internal grounding system; the saildrive is not. Yanmar does not do this. Talk to anyone familiar with the subject, and you will usually hear lots of problems with Yanmar and corrosion and few with Volvo.

With conventional engine systems, a proper grounding system is never floating. The engine is connected to seawater through the shaft. The user can break this path of certain flex couplers.

In our case, we isolate the prop shaft from seawater by mounting the bearings in polymer housings. This breaks the electrical connection, minimizing the risk of corrosion issues due to connection to shore power in a marina. You should “ground” the negative battery as per E-11. This protects from electrical shock while connected to shore power while minimizing the risk of corrosion to your propeller and shaft. The motor and frame are grounded to the B- terminal on the motor controller, so you need not worry about connecting the frame to the grounding system.

You should connect the 48Vdc and 12Vdc negatives at one point to form a common dc negative bus. Do this by connecting the negative terminal of the 12Vdc and 48Vdc batteries. You could do this at a common ground stud, for example. They should only connect at one point.

Do not ground it to the water. There should be a connection to the ac safety ground (green wire), preferably through a galvanic isolator.

Let us assist you in designing your system, use the form below, and we can then discuss a plan for utilizing the optimum EY Quietorque™ or Hybrid System, Battery Bank options, and Charging Methods based on your specific requirements and time frame.